Most of us here share quite a bit in common, and frequently one of those things is a mentor. Over the past several years two people have really come to stand out in my mind in this regard. They’ve both given of their own time and talent to help me personally, and I’ve seen them help dozens of others as well. In fact, when I make a list of my favorite people to dive with, most of them have been mentored or trained by one of these two wonderful people. So I want to turn the spotlight on Bob (grateful diver) and Lynne (LCF). Thank you both for your spirit of giving and sharing. What do they have to do with the DIY thread? Well, I just finished a little DIY project, and if things went according to plan a little something showed up in their mailboxes today. Months ago Sounder pieced together the clues and figured out what I was doing. Since that time he's been my motivator, pushing me to finish this project, so one of these is in his mailbox as well. Thanks Doug. It would probably only be half finished if it weren't for your friendly nudges. Penelope actually got one before any of you. She stood in line at Underwater Sports for hours to pick up some new tanks for me at their sale this year. Thanks, P! You're an awesome friend!

OK, here are the project photos straight from Santa’s workshop…

My interpretation of "how to make a dive knife":

Step 1: Find the right alloy. I chose

this one. It rocks. I don't think there's a better alloy for this application anywhere.

Step 2: Get the French manufacturer to send some. They wouldn’t take my money. They wanted a knife instead. Turns out most of them are divers. They got the first prototype.

Step 3: Figure out what this thing’s going to look like. Here are a few of the various design drawings.

Step 4: Transfer the pattern to steel and rough-cut on the metal bandsaw.

Step 5: Clean up on the belt-grinder (which was another DIY project), and drill some holes.

Step 6: Heat treat. Bad things happen when you mix high-alloy stainless steels with heat and oxygen. So, the blades go into an air-tight sacrificial stainless-steel foil envelope. Be careful, stainless foil is sharp.

Step 7: Into the heat treat furnace (which was another DIY project). This alloy gets a timed soak at 1,922 Fahrenheit (temp controller reads in Celsius).

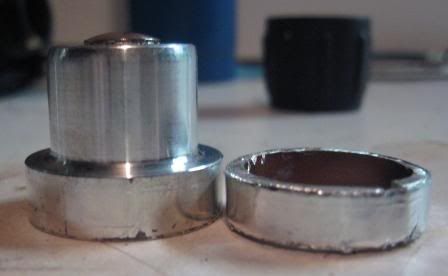

Step 8: The foil packet gets pulled from the furnace and quenched to room-temp. This has to be done quickly. It goes from 1,900 degrees to room temp in about 40 seconds.

Step 9: Some high-alloy stainless steels are stubborn, not reaching full hardness without a cryogenic treatment following the quench to room-temp. This steel is one of those, and so at this point it goes into the liquid nitrogen (-321F) for 2 hours.

Step 10: Blade gets tempered twice at 356 degrees Fahrenheit. Tempering will relieve the stresses created by hardening. Then it gets cleaned up and the main bevels ground on the belt grinder.

Step 11: Time to put handles on this thing. Sure looks ugly, doesn’t it! The handles (scales) are micarta, which is canvas laminated with epoxy. It’s like fiberglass, but made with cotton instead of glass fiber. Don’t worry, it’ll look better soon. Scales are applied with 10-ton epoxy, brass pins and clamped up.

Step 12: Tape off the blade and grind away the excess handle material. Shape the handle, sand, sand ,sand, sand, and polish. Ta Da. There it is. 80% more corrosion resistant than 440c, harder than beta-alloy titanium, and a nice stout 4mm thick spine. I think I’ll call it the Orca, because it’s ready to take on anything in Puget Sound.

Step 13: Need a secure way to carry it. Sheath is kydex. Knife snaps into the sheath for possitive retention, but a 1/8" bungee loop stretched over the sheath gives a little extra security and doubles as a wrist-strap. Working kydex is pretty easy. Cut it with a saw, heat it, mold it to shape, buff the edges, and that's about it.

"The place looked like a washing machine full of Josh's carharts. I was not into it." --Sockmonkey