I'll start off with some random bits of info as to why I wanted the stand:

- I'm 6'1", It's a challenge to get into without a tall bench.

- I wanted somewhere to put my Argon Bottle

- I like the idea of sidemounting my BOBs

- I needed someway of lifting the thing without hurting my fingers

Enter, My 3D CAD software!

In a previous (working) life, I was a mechanical designer. Specifically, I worked with sheet metal, primarily SS.

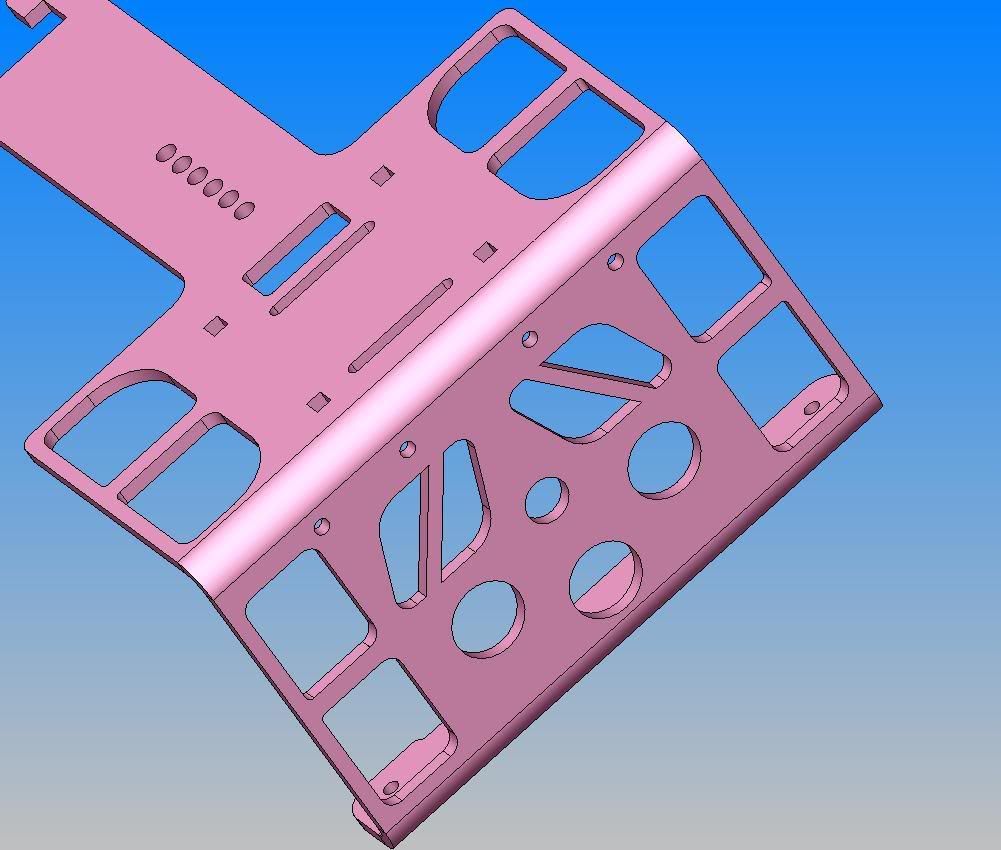

I started with a list of things I wanted the stand to have.

- No Sharp Corners - all corners were to be rounded. All edges softened

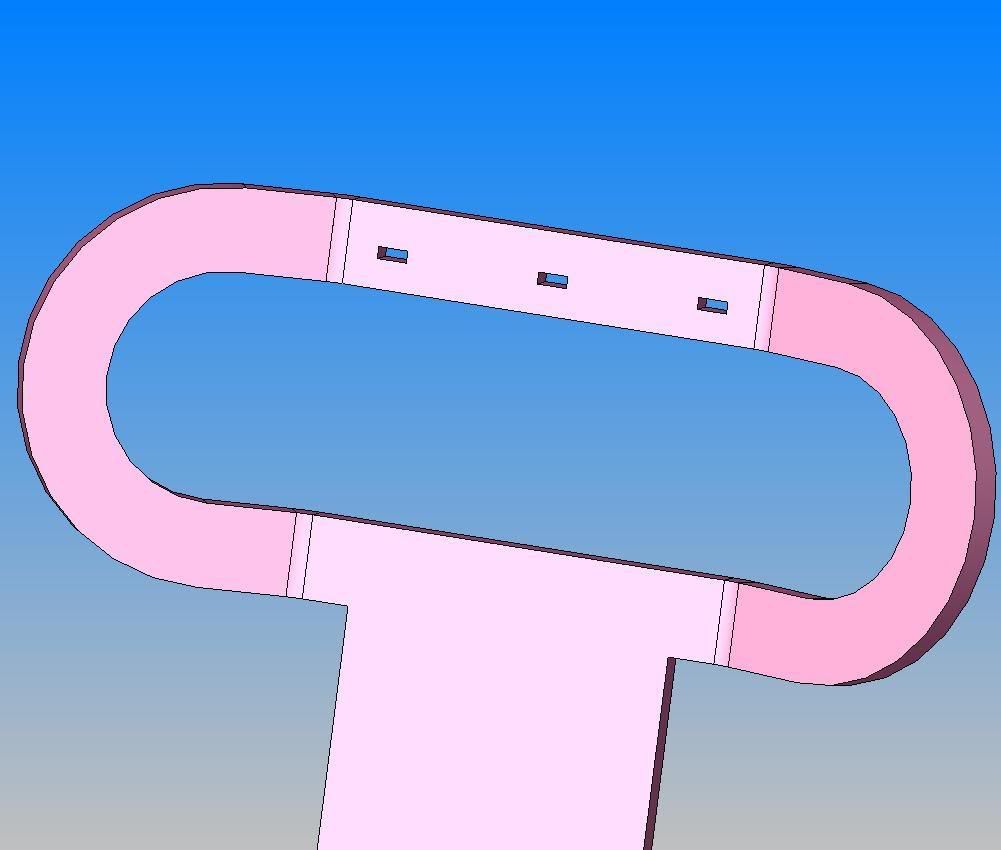

- A lifting handle that doesn't get in the way of my hoses

- Easy to Travel with - Must break down to be no bigger than my CCR

- Somewhere to fit my argon bottle

- Height, for easier Donning and Doffing

- Simple to use/install

- light - I went with Aluminum- I don't need much weight as is (I'm down to 6 lbs, with al. tanks and drysuit)

- Ability to attach 'stuff' to it, including acting like a butt-plate for sidemounting

Then I started thinking ... What about the Sport KISS. I started chatting with a SK owner and he was nice enough to take some measurements for me. The design then was made to also fit a SK, with one part being replaced.

Thus, I produced the 'Travel Stand'

It wasn't cheap to get a single, one-of, made, but I think it was a good choice for me.

Taken apart (ie, for travel packing):

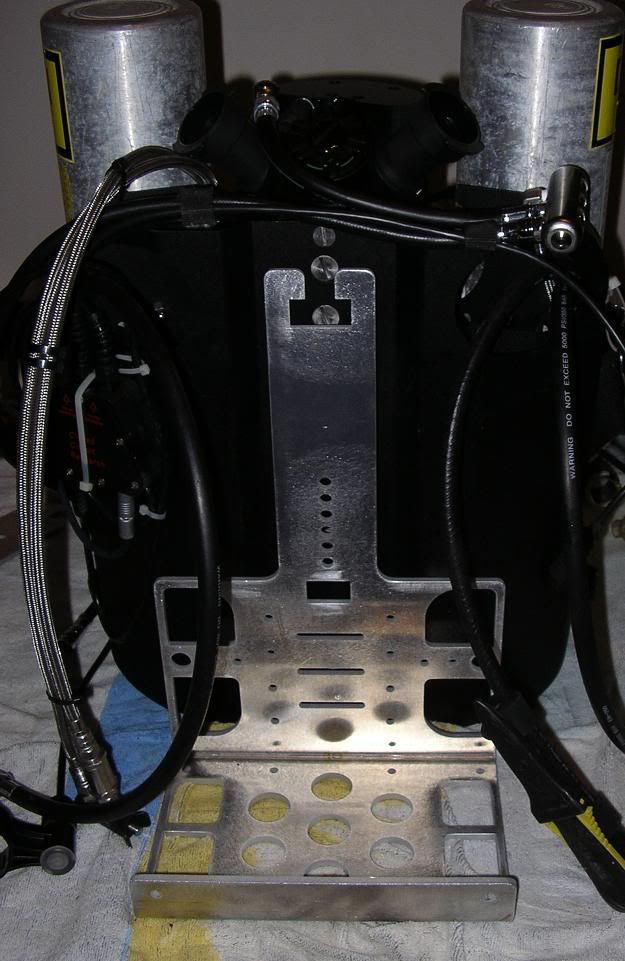

And Mounted on a Sport:

After several dives, I am quite happy with the way everything worked out. I have some new ideas, and have made drawings for them too. Little things I learned from the first stand to make it fit my needs even better:

- No tools required for removing the Back-plate

- A little shorter (I was having a little trouble reaching the bottom)

- A little smaller Handle

- A place to attache zip-ties to the handle for holding extra gear (ie, zip-tie on a D-ring for holding stuff up while not wearing the unit.

- An Argon Bottle mounting bracket - so the bottle isn't right up against the side of the stand - I found it hard to attach things easily. At the moment, I've rigged somethign up that works, but kinda looks stupid (so no pictures )

Once I get some spare cash, I'm going to get the new one made. I'll try to post some pics for that too - but it may be a while

Some Pics of the new design:

If anyone is interested in more pictures, You can find them here:

http://s279.photobucket.com/albums/kk15 ... Prototype/

What do you folks think??

Scott